Here, we expand our study to other materials relevant to the semiconductor industry: Ge, C, W, GaN, and SiO 2. Previously, we published an overview of ALE focused on Cl/Ar etching of Si. The cycle is repeated until the desired depth is reached. The basic concept involves splitting the etch process into at least two separate steps: first modifying the surface and second removing the thin modified layer. Lam Research Corporation, “ Lam research introduces dielectric atomic layer etching capability for advanced logic,” 2016. Atomic layer etching (ALE) is a multistep process for removing ultrathin layers of material and is used today in the fabrication of 10 nm logic. The structures going into our smartphones and other connected devices have become so small that they require atomic-scale processing. The field of plasma etching is more critical than ever to the formation of nanometer-sized features in advanced chip technology. They conclude that ALE is both simpler to understand than conventional plasma etch processing and is applicable to metals, semiconductors, and dielectrics. This insight explains why some materials are more or less amenable to the directional ALE approach. By systematically studying atomic layer etching of a group of materials, the authors show that ALE synergy scales with the surface binding energy of the bulk material. Synergistic behavior is observed for all of the systems studied, with each exhibiting behavior unique to the reactant–material combination. ALE synergy is related to the energetics of underlying surface interactions and is understood in terms of energy criteria for the energy barriers involved in the reactions. This parameter is inspired by the ion-neutral synergy concept introduced in the 1979 paper by Coburn and Winters. The authors analyze these systems by defining an “ALE synergy” parameter which quantifies the degree to which a process approaches the ideal ALE regime. In this article, the authors report on ALE of Si, Ge, C, W, GaN, and SiO 2 using a directional (anisotropic) plasma-enhanced approach. As it stands, Synergy’s configuration of screens depends on either hand-editing a text file, or a GUI interface that didn’t take human beings into account.Atomic layer etching (ALE) is a multistep process used today in manufacturing for removing ultrathin layers of material.

The biggest problem Synergy has for usability is a huge interface problem. In the past few days they released the first release under FOSS, brining Synergy back to awesome status. Eventually the project moved to it’s new home, Synergy-FOSS.

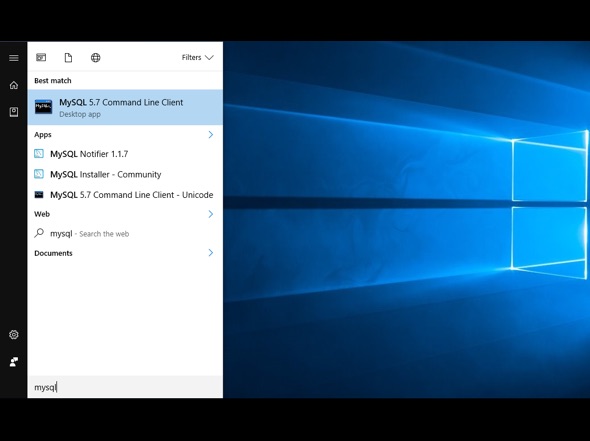

#SYNERGYKM BINARIES WINDOWS SOFTWARE#

There were a few groups trying to make the software work, but a project named Synergy++ came out on top as the successor to the project providing a good chunk of maintenance to the Synergy code.

#SYNERGYKM BINARIES WINDOWS WINDOWS#

New operating systems, namely Windows Vista & 7, required maintenance on the software. The maintainer for the original project at Synergy.sf.net went AWOL. Just a bit curious to set up with Windows as the “server” (the computer with the physical keyboard & mouse).Īs wonderful this software is, the development story was questionable in the late 2000’s. I invite you to use Synergy now as it’s stable.

As you’ll read on, we’re now at a point where the setbacks are worked on. Right now the project is recovering from a bit of neglect as well as a lack of user-centered focus on design.

Even more amazing is that text-only copy and paste works across the computers! Have one computer with more than one screen? Synergy adjusts flawlessly. Once they’re set up with Synergy, you use one keyboard and mouse to run as many computers as you wish. It doesn’t matter what OS the computers are using.

0 kommentar(er)

0 kommentar(er)